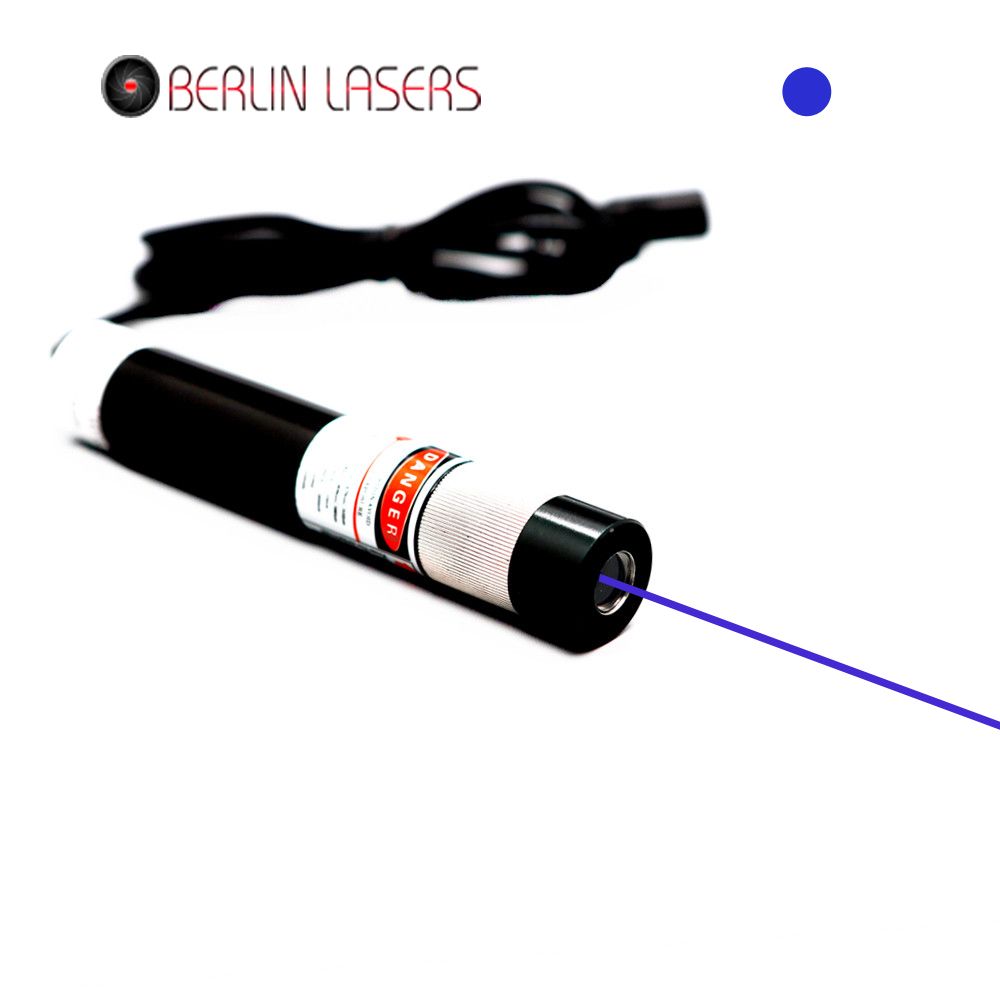

In process of current time industrial laser marking works, the short wavelength of 445nm made device of blue laser diode module always projects high energy density and highly bright blue laser beam emission from an inner blue laser diode. It gets excellent suitability of highly reflective materials. Blue laser light has a short wavelength, and metals have a high absorption rate. Especially for highly reflective metals like copper and aluminum, the 445nm blue dot laser module absorbs it better than infrared lasers, making it effective for marking. Based on the use of correct output power and proper operating voltage DC power supply, it is suitable for different materials and marking requirements, achieving marking depths and effects of varying depths. Whether shallow surface marking or deep engraving, it can effectively accomplish the task.

There might be a lot of working surfaces where factory workers or engineers would be in need to make ultra clear and precise dot indication for further laser marking works. 445nm blue laser diode module gets much shorter wavelength of 445nm than any other visible optical spectrum, however, it still gets higher laser energy density, and enables rapid and effective marking on the surface, improving marking efficiency greatly. In order to make sure of its long time lasting blue laser light source and blue dot indication onto marking surfaces, typically blue dot laser alignment is equipped with a constant temperature and constant current circuit board, combined with an internal metal heat dissipation system, this blue laser maintains stable blue beam output over long periods of continuous operation, ensuring consistent marking results.

According to the special use of a compact structure design of 16mm, 18.9mm and 26mm diameter tube for different output power range, the genuine use of a 445nm blue laser diode module is compact and light in weight, which makes it easy to install and integrate into various laser marking equipment. Cooperated with adjustable focus optic lens, this glass coated lens made blue laser enables immediate blue laser light source focusing at beam aperture, and converts into an increasing accuracy and brightness blue dot indication at longer distance and higher lighting occasions as well. Owing to its excellent heat dissipation design and stable circuit board driving circuit board design, this blue dot laser always boasts a long serving lifetime of more than 8,000 hours under normal operating conditions, reducing maintenance and replacement costs.

Based on correct use of output power and operating voltage electric power source supply, this 445nm blue laser diode module always enables easy installation or integration with industrial laser marking device, and makes sure of no mistake and high speed dot marking onto a lot of raw material surfaces. Its major applications are as below:

Material Surface Marking: It can mark surfaces of various materials, including metal, plastic, wood, and leather. For example, it can mark trademarks and model numbers on metal products and engrave product serial numbers on plastic casings.

Fine Pattern Engraving: Due to its small spot size, blue alignment laser can engrave fine patterns and text. It is suitable for personalized decorative marking on crafts and jewelry, and can create delicate patterns, designs, and tiny text.